• Welcome to https://albinowners.net, home of Albin Owners Group!

• If you don't remember your password, use the I forgot my password link to reset it.

• Contact Us if you have any questions. If you're not receiving our email, include a phone number where we can text you.

• If you don't remember your password, use the I forgot my password link to reset it.

• Contact Us if you have any questions. If you're not receiving our email, include a phone number where we can text you.

FAQ:

• Membership information

• Burgees

• How to post photos

• Membership information

• Burgees

• How to post photos

Maintaining those Colored Hulls

-

RicM

- Gold Member

- Posts: 1209

- Joined: Sat Dec 02, 2006 10:06 am

- Location: Wickford RI

- Contact:

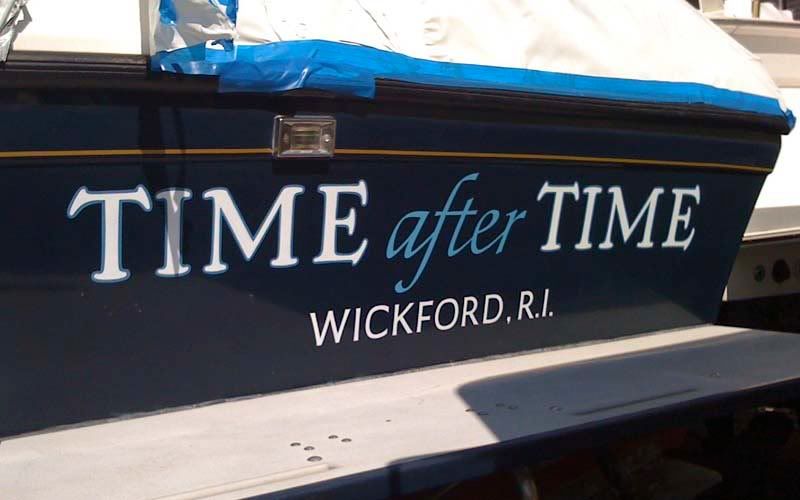

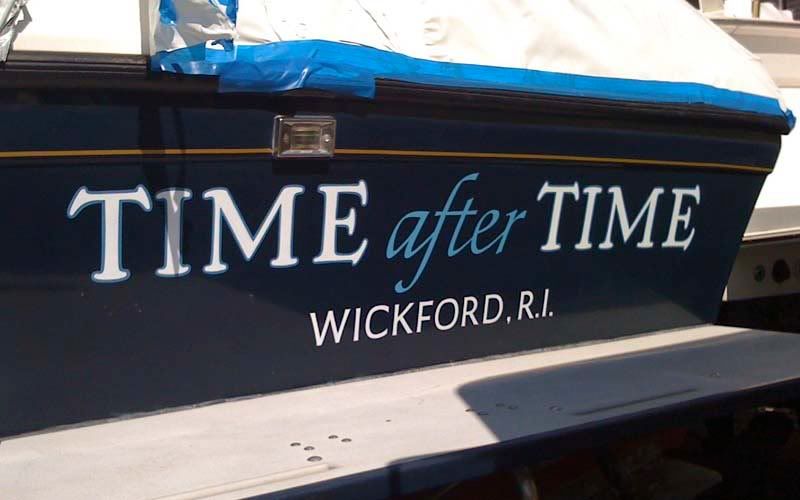

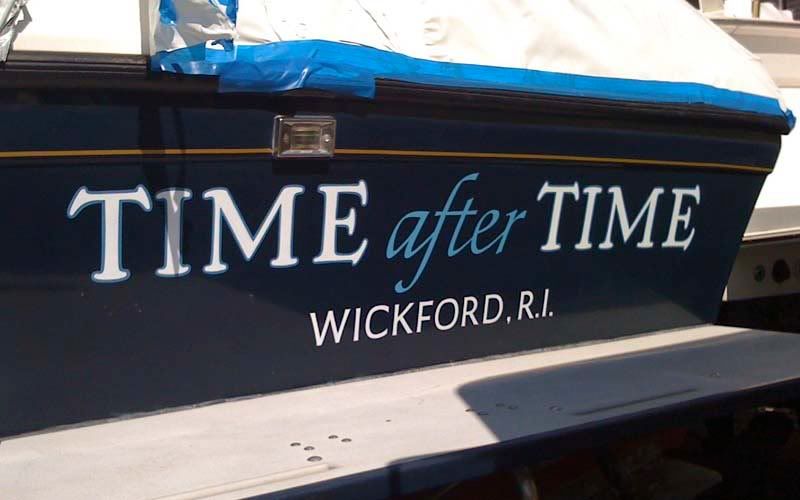

2 Days of buffing

My arms and back are killing me, but I have completed the hard work on the port side of Time After Time, and finally got the name on the transom too. I got one coat of Rejex on yesterday, and was not blown away by the finish. It did go on and buff off easily. I do plan on applying several coats to increase durability and they say it needs 24 hrs to really "cure". We shall see. I had a local sign guy, Rob Blaise hand paint the transom. He does great work and I really like "real" lettering versus machine cut vinyl. Getting close to splash day, hopefully May 1!

Ric Murray

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

-

Legacy

- Gold Member

- Posts: 411

- Joined: Mon Apr 17, 2006 1:40 pm

- Boat Make/Model (or None): Albin 35te

- Home Port: Boston, MA

- Location: Boston

- Contact:

Looks great

Looks terrific. If you're bored, my hull is waiting! Lettering look great.

Rick

Rick

Rick

1998 Albin 35TE

"Legacy"

1998 Albin 35TE

"Legacy"

-

RicM

- Gold Member

- Posts: 1209

- Joined: Sat Dec 02, 2006 10:06 am

- Location: Wickford RI

- Contact:

Bored?

Bored? I'm panic stricken! I have a helm that looks like it's been fragged, the cabin is a tool shed, a half installed alarm system, an auto pilot sitting in a box that needs to be plumbed into the hydraulics (HELP!) a starboard side that needs a second pass with compound and and a couple of coats of sealant. I need a 500 hr service (adjust valves with a certified Yanmar mechanic).....and I have 4 weeks to launch! Bored? I don't think so!

Karen & I are excited about our trip to Boston though and looking forward to it, I want everything shipshape for that trip.

Karen & I are excited about our trip to Boston though and looking forward to it, I want everything shipshape for that trip.

Ric Murray

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

-

saltshaker28

- Gold Member

- Posts: 225

- Joined: Thu Jul 05, 2007 6:42 pm

faded hull

Ric I was wondering what kind of machine did you use to apply the 3m extra duty

-

saltshaker28

- Gold Member

- Posts: 225

- Joined: Thu Jul 05, 2007 6:42 pm

maintaning those discolored hulls

I would like to know what kind of polishing,buffing tool is used to apply the 3m extra duty compound

- jcollins

- In Memorium

- Posts: 4927

- Joined: Sun Apr 16, 2006 9:05 pm

- Boat Make/Model (or None): Boatless

- Home Port: Baltimore

- Location: Seneca Creek Marina

- Contact:

- Mariner

- Gold Member

- Posts: 1455

- Joined: Mon Apr 17, 2006 11:18 am

- Location: Gig Harbor, WA

I use 3M Cleaner Wax (or Restorer Wax, if the hull is really bad) and a wool buffing bonnet, on my Makita 10,000rpm angle grinder. It makes very quick work of fiberglass hulls. I tried doing it by hand once last summer, and I'll never do it again. The whole hull can be done in about 15 minutes with the high-power buffer, as where it takes a couple hours with a normal buffer, and all day by hand.

This is not the kind of thing you'll find at Home Depot. Fastest I've seen there was 6,000rpm. Though, I'm inclined to think that would work just fine. 10,000rpm is a bit much. It sucks against the hull when you're working with it, and will throw a traditional "tie-on" type bonet 100' in the air as soon as you hit the switch.

I polished the hull on my new 18' Boston Whaler with it today, and it took me about 5 minutes to do the whole boat.

This is not the kind of thing you'll find at Home Depot. Fastest I've seen there was 6,000rpm. Though, I'm inclined to think that would work just fine. 10,000rpm is a bit much. It sucks against the hull when you're working with it, and will throw a traditional "tie-on" type bonet 100' in the air as soon as you hit the switch.

I polished the hull on my new 18' Boston Whaler with it today, and it took me about 5 minutes to do the whole boat.

-

RicM

- Gold Member

- Posts: 1209

- Joined: Sat Dec 02, 2006 10:06 am

- Location: Wickford RI

- Contact:

Buffers

The recommended speed for compounding is around 2000-2500. The issue is you can overheat the surface at higher speeds if you are not careful about keeping the machine moving. I agree that the "tie on" pads are a pain to useless. See:

http://www.autogeek.net/bupo.html

for a full line of velcro pads that stick great on the Harbor Freight grinder and any other velcro type backer.

Here is info on using a circular polisher:

http://www.autogeek.net/buffer-polisher.html

http://www.autogeek.net/bupo.html

for a full line of velcro pads that stick great on the Harbor Freight grinder and any other velcro type backer.

Here is info on using a circular polisher:

http://www.autogeek.net/buffer-polisher.html

Ric Murray

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

- RobS

- Gold Member

- Posts: 4052

- Joined: Wed Oct 03, 2007 6:20 am

- Boat Make/Model (or None): Chris Craft TSF

- Home Port: Center Moriches, NY

- Contact:

I have the Hitachi SP18VA 7" Polisher with Hook & Loop Pad. I like this machine for the loop handle so you can grip it aty different positions. Helps with hand/wrist fatigue and for working in different posistions or angles. The hull looks like a new car after 3M Perfect -It Extra Cut & then 3M Perfect-It Rubbing Compound with the machine and a coating of Nu Finish by hand. The speed control dial on the polisher is a must in order to work the compounds at intended rpm. I ran it just shy of 2000rpms. I'll post some hull/transom shots soon.

You do not have the required permissions to view the files attached to this post.

Rob S.

"TENACIOUS"

1974 Chris Craft 36' Commander Tournament

Cummins 6BTA 330B's

(Former Owner)

"TOY-RIFIC" 2000 28TE, 6LP, Hull 408

Luck is the residue of good design.

"TENACIOUS"

1974 Chris Craft 36' Commander Tournament

Cummins 6BTA 330B's

(Former Owner)

"TOY-RIFIC" 2000 28TE, 6LP, Hull 408

Luck is the residue of good design.

- RobS

- Gold Member

- Posts: 4052

- Joined: Wed Oct 03, 2007 6:20 am

- Boat Make/Model (or None): Chris Craft TSF

- Home Port: Center Moriches, NY

- Contact:

Here's a couple shots, not the greatest - taken with cell phone - but you can see the shine. I also took of the Port-Of-Call which will be replaced this week....

You do not have the required permissions to view the files attached to this post.

Rob S.

"TENACIOUS"

1974 Chris Craft 36' Commander Tournament

Cummins 6BTA 330B's

(Former Owner)

"TOY-RIFIC" 2000 28TE, 6LP, Hull 408

Luck is the residue of good design.

"TENACIOUS"

1974 Chris Craft 36' Commander Tournament

Cummins 6BTA 330B's

(Former Owner)

"TOY-RIFIC" 2000 28TE, 6LP, Hull 408

Luck is the residue of good design.

-

RicM

- Gold Member

- Posts: 1209

- Joined: Sat Dec 02, 2006 10:06 am

- Location: Wickford RI

- Contact:

Polisher

Looks pretty similar to this one for 29.99 from Harbor Freight:

http://www.harborfreight.com/cpi/ctaf/d ... mber=92623

which is the one I've been using, also at about 2000 RPM on the speed dial. I wish I had started with Perfect -It Extra Cut, I used Extra Duty which is not as aggressive, then Finesse-it. It looks 100% better, but I can still see some of the pattern of oxidation in direct sunlight when viewed from 2 ft away. I have decided not to worry about it, it looks great from 10 ft and it's gonna be smeared with fish blood in a few weeks anyway!

http://www.harborfreight.com/cpi/ctaf/d ... mber=92623

which is the one I've been using, also at about 2000 RPM on the speed dial. I wish I had started with Perfect -It Extra Cut, I used Extra Duty which is not as aggressive, then Finesse-it. It looks 100% better, but I can still see some of the pattern of oxidation in direct sunlight when viewed from 2 ft away. I have decided not to worry about it, it looks great from 10 ft and it's gonna be smeared with fish blood in a few weeks anyway!

Ric Murray

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

Big Time, 42' 1993 Jersey Sportfish

Formerly owned Time After Time, 2003 28TE

Wickford RI

- RobS

- Gold Member

- Posts: 4052

- Joined: Wed Oct 03, 2007 6:20 am

- Boat Make/Model (or None): Chris Craft TSF

- Home Port: Center Moriches, NY

- Contact:

Thanks Ric. Love the name on yours, looks real classy. Also loved your quote, "the cabin is a tool shed" - I have a few projects going on too so I could relate and had a good laugh when I read that one.

Rob S.

"TENACIOUS"

1974 Chris Craft 36' Commander Tournament

Cummins 6BTA 330B's

(Former Owner)

"TOY-RIFIC" 2000 28TE, 6LP, Hull 408

Luck is the residue of good design.

"TENACIOUS"

1974 Chris Craft 36' Commander Tournament

Cummins 6BTA 330B's

(Former Owner)

"TOY-RIFIC" 2000 28TE, 6LP, Hull 408

Luck is the residue of good design.

- Mariner

- Gold Member

- Posts: 1455

- Joined: Mon Apr 17, 2006 11:18 am

- Location: Gig Harbor, WA

Re: Buffers

I know that the speed I'm using is way above what anyone would recommend. But as for overheating, at that speed, you don't need to spend more than a second or two above any given spot. I pretty much just walk it down the side of the hull, never stoping, going back and forth in rows like a lawnmower. The gelcoat is still cool to the touch after it gets buffed, so I'm not worried about that. Also, although the grinder is rated at 10,000 rpm, I doubt it turns more than half that with the extra weight of the big bonnet on it. It runs noticably slower with the bonnet than it does with a sanding pad on it.RicM wrote:The recommended speed for compounding is around 2000-2500. The issue is you can overheat the surface at higher speeds if you are not careful about keeping the machine moving. I agree that the "tie on" pads are a pain to useless. See:

http://www.autogeek.net/bupo.html

for a full line of velcro pads that stick great on the Harbor Freight grinder and any other velcro type backer.

Here is info on using a circular polisher:

http://www.autogeek.net/buffer-polisher.html

Still, though, the power of that thing is really something to behold. The first time I tried to put a normal tie-on bonnet on it, I clicked the trigger and literally faster than my eyes could even perceive what had happened, the bonnet was gone. I looked around and didn't see it. So I looked up to the sky, and saw it up there, about 100' in the air, falling back to earth, drifting with the wind into the neighbor's back yard! Tried a "hook and loop" bonnet and it produced the same results, except this time it launched it against the garage door, leaving a dent the size of a quarter. Keep in mind this thing is made of WOOL. So, I now use one that has a hole in the center and attaches like a sanding wheel. The thickness of the wool protects the gelcoat from the spinning flat nut in the center. The centrifugal force causes the bonnet to spin all the air out of it and produces a vacuum when you place it against the hull. As soon as it gets about 3" from the hull, it suddenly sucks it tight against it. You have to use a LOT of wax, as it will sling the excess pretty far. My entire driveway has a coating of the stuff right now. Before using it, I usually move the cars out into the street to keep them clean.

-

saltshaker28

- Gold Member

- Posts: 225

- Joined: Thu Jul 05, 2007 6:42 pm